Blister

Packaging Machines

- Home

- our solutions

- Blister Packaging Machines

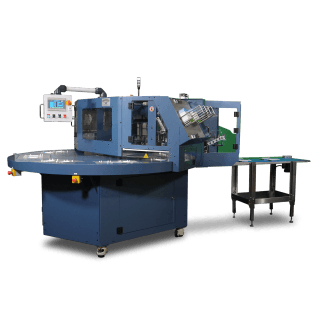

Starview’s Fully Automatic Blister Packaging Machine FAB with APB Series with auxiliary All Paper Blister feeder option

Environmentally friendly packaging materials just got economically processed with Starview's Ecological Solution for CPG Carded Packaging!

Starview’s FAB APB Series are fully automated rotary type blister sealing machines are ideal for high volume or JIT production. Given the proper conditions certain models of these machines are capable of up to 20 cycles per minute in production. The All-Paper Blister is part of Rohrer's ezCombo program

FAB APB series detailsStarview’s High Volume Fully Automatic Inline Blister Sealing Machine

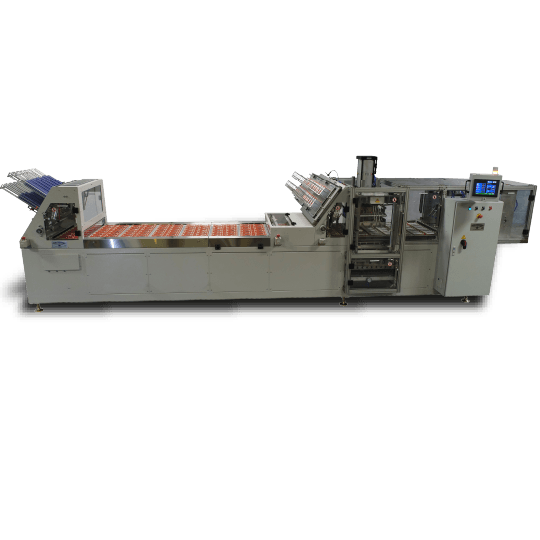

CBS series Automated Inline Conveyor type blister sealing machines are ideal for high volume or JIT production. Given the proper conditions these machines are capable of up to 20 cycles per minute in production. Starview’s automated inline conveyor blister sealing machines are built with the capability to feed blister(s), blister card(s) and discharge finished packages when proper tooling is installed.

CBS series details

SB SSB series

manual shuttle |

MS2 series

manual shuttle |

||

| Size type of production: | Small to medium | Small to medium | |

| Nominal sealing area: | 10” x 12” / 14” x 18” | 18” x 24“ / 24” x 30“ / 24” x 36“ | |

| Max. blister depth: | 3.25” | 3.25” | |

| Prod. loading operation: | Manual | Manual 2 stations | |

| Open loading stations: | 1 or 2 | 2 | |

| # of sealing fixtures: | 1 or 2 | 2 | |

| Blister feeder: | N/A | N/A | |

| Card feeder(s): | N/A | N/A | |

| Finished package unloader: | N/A | N/A |

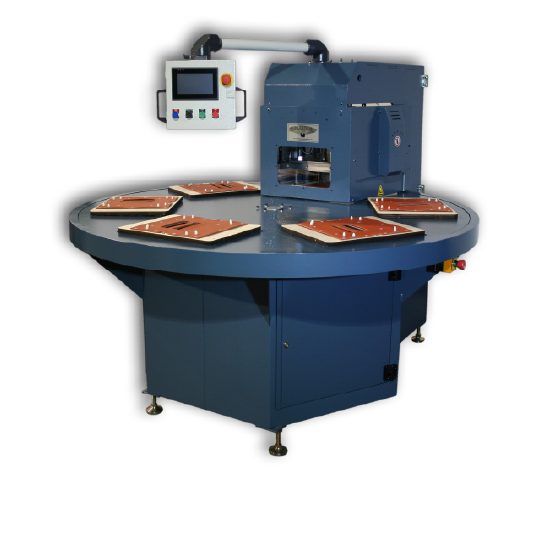

RB series

economical Rotary |

ERB series

semi-Automatic Rotary |

||

| Size type of production: | Medium | Medium to large | |

| Nominal sealing area: | 14” x 18” / 12” x 14“ | 14” x 18” / 18” x 24“ | |

| Max. blister depth: | 3.25” | 3.25” | |

| Prod. loading operation: | Semi-automatic | Semi-automatic | |

| Open loading stations: | 3 or 5 | 5 or 7 | |

| # of sealing fixtures: | 4 or 6 | 6 or 8 | |

| Blister feeder: | N/A | N/A | |

| Card feeder(s): | N/A | Optional | |

| Finished package unloader: | N/A | Optional |

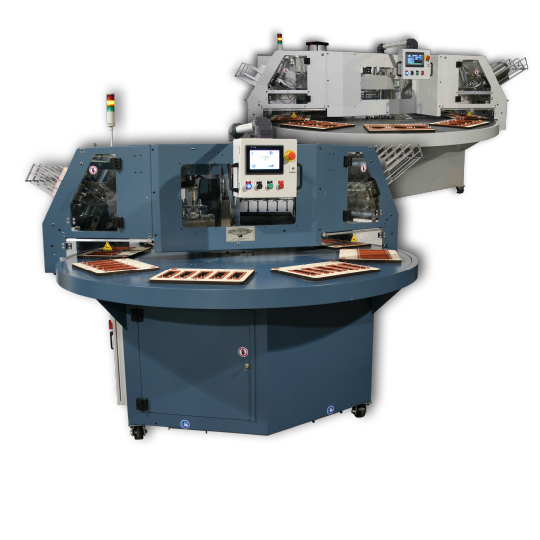

fab4 series

Fully Automatic Rotary |

fab6 / fab8 Series

Fully Automatic Rotary |

FAB APB series

Fully Automatic Rotary

with auxiliary all paper feeder option |

|

| Size type of production: | High volume or JIT | High volume or JIT | High volume or JIT |

| Nominal sealing area: | 10” x 12” / 12” x 16” | 14” x 18” / 18” x 24“ | 14” x 18” / 18” x 24“ |

| Max. blister depth: | 3.25” | 3.5” | 3.5” |

| Prod. loading operation: | Fully automatic | Fully automatic | Fully automatic |

| # of sealing fixtures: | 4 | 6 or 8 | 4, 6 or 8 |

| Open loading stations: | 1 | 2, 3 or 4 | 3 or 4 |

| Blister feeder: | Standard | Standard | Standard |

| Card feeder(s): | Standard | Standard | Standard |

| Finished package unloader: | Standard | Standard | Standard |

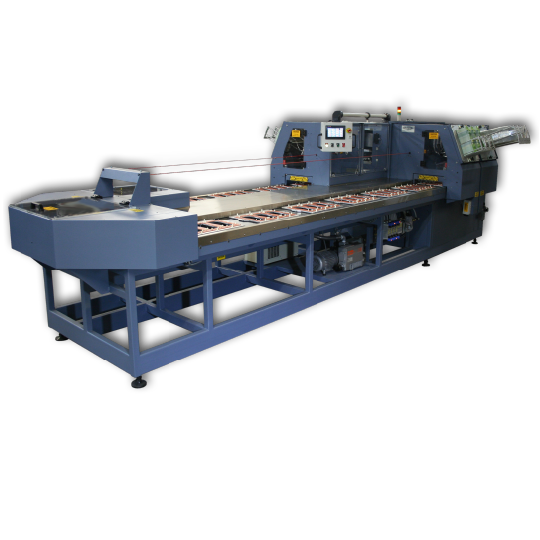

BSC Series

Fully Automatic Carousel

|

cbs Series

Fully Automatic

inline |

||

| Size type of production: | Hight volume | Hight volume | |

| Nominal sealing area: | 14” x 18” / 18” x 24“ | 14” x 28” | |

| Max. blister depth: | 3.25” | 3.25” | |

| Prod. loading operation: | Fully-automatic | Fully-automatic | |

| # of sealing fixtures: | 16 | 16 | |

| Open loading stations: | 9 | 9 | |

| Blister feeder: | Standard | Standard | |

| Card feeder(s): | Standard | Standard | |

| Finished package unloader: | Standard | Standard |