Food Tray

Packaging Machines

- Home

- our solutions

- Food Tray Packaging Machines

Starview’s Manual Shuttle Food Tray Sealer MSTS-1418

Starview’s MSTS Series fare designed and competitively priced for “ready to eat” packaging, typically a clear or printed film to a preformed tray for food manufacturing companies, catering, grocery stores, delicatessens, etc. The MSTS Series is ideal for low to medium production. This series machines can adapt to seal for a wide range of product tray sizes by simply changing the tooling. The MSTS Series machines trim the film to the profile of the tray and automatically rewind the scrap web. The MSTS Series sealers will provide years of dependable performance with a minimum of maintenance.

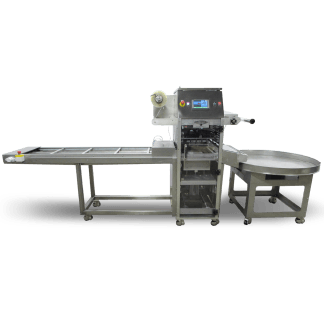

MSTS series detailsStarview’s Custom AITS Series Inline Food Tray Sealing Machine

Starview’s AITS Series are designed and competitively priced for most food tray packaging using a clear or printed film to a preformed tray for food manufacturing companies, catering, grocery stores, etc. The standard AITS Series machines will produce only sealed packages without a modified atmosphere. The AITS Series is ideal for medium production. This series machines can adapt to seal for a wide range of product tray sizes by simply changing the tooling. These machines trim the film to the profile of the tray and automatically rewind the scrap web. The AITS Series sealers will provide years of dependable performance with a minimum of maintenance.

AITS series details more about automation & integration

MSTS Series

Manual Shuttle |

MRTS Series

Manual Two-Station Rotary |

||

| Size type of production: | low to medium volume | low to medium volume | |

| Maximum tray dimensions: | 10.5" x 8.5" or 16.5" x 12.5" | 16.5" x 12.5" | |

| # of open load stations: | 1 | 1 | |

| Vacuum pump installed: | N/A or Standard with MAP | N/A or Standard with MAP | |

| Maximum tray depth: | 3.9” or 4.7” | 4.0” | |

| Registered film: | Optional | Optional | |

| Standard in-feed: | N/A | N/A | |

| Standard out-feed: | N/A | N/A | |

| Average cycle speed without MAP: | 1-4 or 1-6 cpm | 1-6 cpm | |

| Average cycle speed with MAP: | 1-4 cpm | 1-4 cpm | |

| Electrical: | 208-230 Volts / 3PH / 25 Amps | 208-240 Volts / 3PH / 20 or 25 Amps |

AITS-1216 & AITS-1220 Series

Large size Automatic Inline |

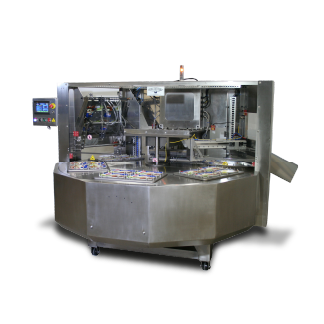

RTS/MAP4-1015 Series

Automatic Rotary Film to Tray |

RBF & RBFA Series

Semi and Fully Automatic Board to Tray |

|

| Size type of production: | medium to high volume | medium to high volume | medium to high volume |

| Maximum tray dimensions: | 10.6” x 17.3“ or 10.8” x 18.5“ | 10.8” x 15.7“ | 15” x 20“ |

| # of open load stations: | 2 or 6 | 1 | 3 or 5 |

| Vacuum pump installed: | Standard | Standard | N/A |

| Maximum tray depth: | 4.3” | 4.3” | 3” |

| Registered film: | Optional | Optional | Optional |

| Standard in-feed: | AITS-1216 : 55" / AITS -1220: 80" | N/A | N/A |

| Standard out-feed: | AITS-1216: 30"/ AITS -1220 : 34" | 30” | N/A |

| Average cycle speed without MAP: | 1-15 cpm | 1-15 cpm | 1-18 cpm |

| Average cycle speed with MAP: | N/A or 1-10 cpm | 1-8 cpm | N/A |

| Electrical: | 208-240 Volts / 3PH / 20 or 25 or 30 Amps | 208-240 Volts / 3PH / 32 Amps | 208-240 Volts / 1PH / 32 Amps or 208-240 Volts / 3PH / 19 Amps |