Thermoforming

Machines

- Home

- our solutions

- thermoforming machines

Starview’s Starview's IF Series vacuum forming machines are designed for medium to high production runs. A standard forming area of 25 x 40 inches is offered. Machines are roll fed with the full formed sheets guillotined at the end of the cycle. An inline film preheating oven, plug/grid assist and male/female mold capability are all standard. IF Series machines will run most thermoforming grade films.

more about this machine

SAT Series

Semi-Automatic Vacuum |

FOM Series

Automatic Vacuum |

||

| Size type of production: | low to medium | medium | |

| Forming Area: | 20” x 30“/ 25” x 30“ / 25” x 40“/ 30” x 36“ |

20” x 30“/ 25” x 30“ / 25” x 40“/ 30” x 36“ |

|

| Cooling blowers: | Standard | Standard | |

| Vacuum pump: | Standard | Standard | |

| Water cooled base: | N/A | Standard | |

| Plug/Grid assist: | Optional | Optional | |

| Adjust film width: | N/A | Optional | |

| Average cycle speed: | 1-4 cpm | 1-4 cpm | |

| Max. form height: | 8” | 5” |

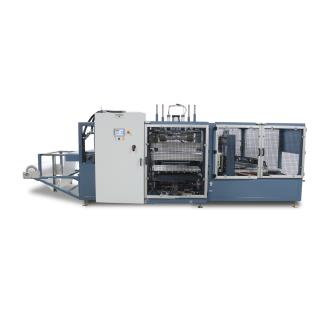

IF Series

Fully Automatic Inline Vacuum |

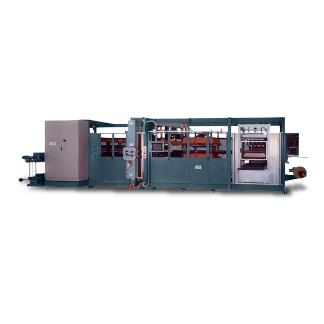

IPV Series

Fully Automatic Inline Pressure |

||

| Size type of production: | medium to high | high | |

| Forming Area: | 25” x 40“ | 25” x 25” | |

| Cooling blowers: | Standard | Standard | |

| Vacuum pump: | Standard | Standard | |

| Water cooled base: | Standard | Standard | |

| Plug/Grid assist: | Standard | Standard | |

| Adjust film width: | Standard | Standard | |

| Average cycle speed: | 1-8 cpm w/upper oven & 1-12 w/upper and lower ovens | 5-25 cpm | |

| Max. form height: | 4” | 8” |